At the moment, we are welding lap-joint flanges directly to the piping. Is this an acceptable method of employing lapped flanges, or should I switch to slip-on flanges?

I understand that lapped flanges are typically utilized with but ends to allow for rotation as necessary, however I am unsure whether or not a lapped flange should be welded.

Kindly advise on the proper application of flanges.

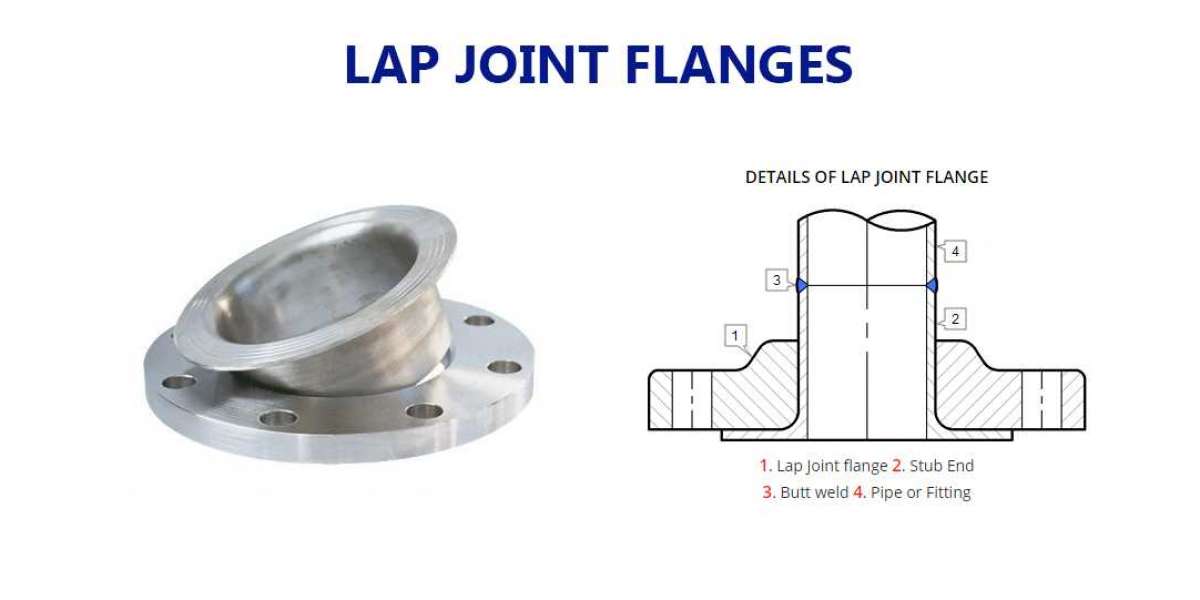

Lap joint flanges are very similar to slip-on flanges, with the primary distinction being that the bore and face of the flange have a curved radius to accommodate a lap joint stub-end. Lap joint flanges and stub-end assemblies are frequently utilized in applications that need regular disassembly for inspection.

Slip-on Flanges: (SO) Certain contractors favor flanges over weld-necks because of their lower initial cost. However, the additional expense of the two fillet welds necessary for appropriate installation may balance this benefit. While the slip-on flange's strength is adequate for its rating, its life under fatigue is estimated to be just one-third that of the weld-neck flange.

The slip-on flange can be fitted to the end of a pipe or to one or more of the fitting's ends. The slip-on flange is positioned so that the pipe or fitting's inserted end is set back or short of the flange face by the thickness of the pipe wall plus 1/8 of an inch. This enables a fillet weld equivalent to the thickness of the pipe wall to be made inside the SO flange without causing damage to the flange face. Additionally, the back or exterior of the flange is welded with a fillet weld.

Additionally, a Slip-On flange is available. This is the Reducing Slip-On Flange. This is essentially a larger (say, a 14-inch) version ") Slip-On flange blank that has the center (pipe) hole cut out (or drilled out) for a 6" (or other size) pipe instead of a 14" (or other size) pipe. The SO Reducing flange is primarily used to reduce the size of the line when space constraints prevent the use of a weld neck flange and reducer combo. The Slip-On Reducing Flange should be used exclusively in applications where the flow direction is from the smaller to the larger size.

Lap Joint Flanges are a two-piece device similar to a weld-neck flange but also similar to a loose slip-on flange. One piece is a sleeve known as a 'Stub-end sleeve "and is formed like a short section of pipe with one end having a weld bevel and the other having a narrow shoulder called the hub. The hub has the same outside diameter as a weld neck flange's raised face (gasket contact surface). The hub is typically between 14 and 3/8" thick. A rounded transition (or inner fillet) connects the hub to the sleeve on the back face of the hub.

The backing flange is the other component of a lap joint flange. This flange has the same general measurements as other flanges (O.D., bolt circle, bolt hole size, etc. ), but it does not have a raised face. On one side, the backside, there is a little shoulder with a square cut center or pipe hole. The front side has a flat face and an outside fillet matching the fillet on the "Stub-end" piece at the center hole. The lap-joint flange assembly's flange is slipped onto the stub-end prior to welding the sleeve to the adjacent pipe or fitting. The flange is not welded or otherwise secured. It is free to spin in whatever direction necessary to ensure perfect alignment with whatever it is connecting.

Typically, the "Stub-end" is available in two lengths. There is a short version (about 3") and a lengthy version (around 6"). It is prudent for the piping designer to be aware of the piping specification's version number.

Due to its two-piece construction, the Lap Joint Flange enables cost savings and simplifies work. The cost savings occur when the pipe system necessitates the use of a high-priced alloy for all "wetted" components in order to prevent corrosion. The sleeve or stub-end can be made of the more expensive alloy, but the flange can be made of the less expensive forged carbon steel.

Work simplification is necessary in situations where frequent and rapid disassembly and reassembly are required during the operation of a plant. The flexibility to rotate the backing flange compensates for bolt hole misalignment during reassembly.