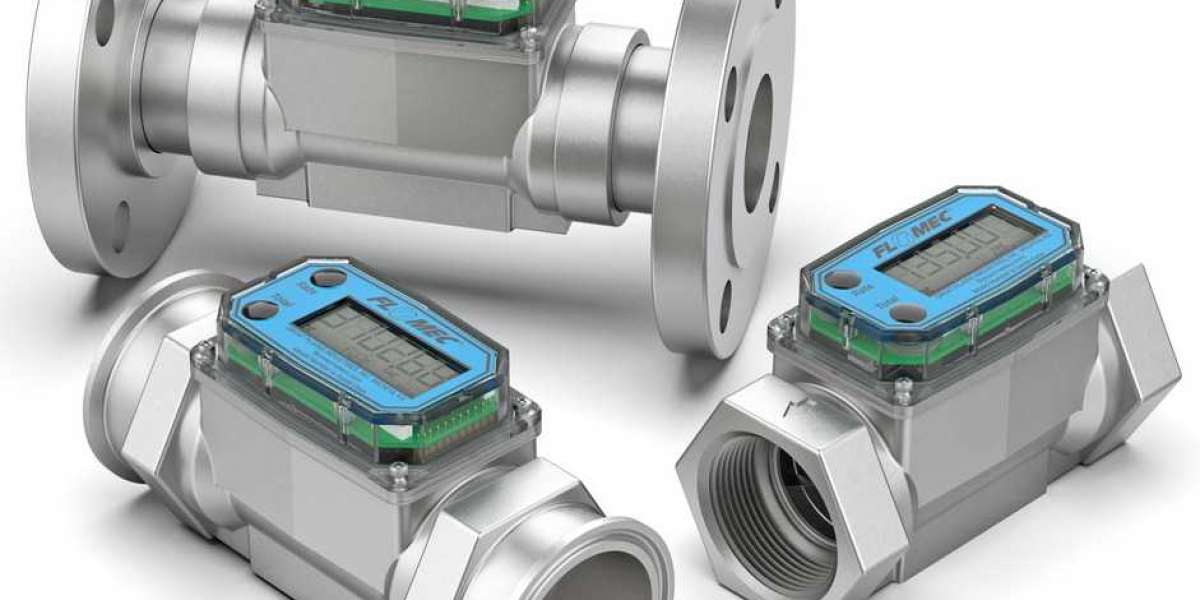

The rotation of the shaft can be sensed mechanically or by detecting the movement of the blade. Knife head fitness exercises are generally tested with a magnetic method, and each knife head or inserted copper piece causes a single pulse. Turbine flowmeter controllers are generally located outside of the fluid flow to prevent the use of wet controllers will cause structural restrictions on raw materials. When the fluid moves quickly, it will cause a large number of single pulses. The signal transmitter resolves the differential signal to clarify the fluidity of the fluid. Smart transmitter and sensor technology system software can be used to verify the total flow of forward and reverse fluidity orientation.

Advantages and disadvantages of turbine flow meters:

The cost is moderate. It is very suitable for cleaning with moderate and steady rate, and high viscosity fluids. The reduction is very good, because it can load extremely low ** total flow. If put in the cleaning liquid, especially in the case of wetting, they are reliable. AGA and API are approved for trade work handover. They do cause some work pressure to decrease, which will be an element of force fluidity, for example. Not reliable for steam.

Turbine flowmeters are used to accurately measure the water flow of liquids, vapors and vapors in pipelines, such as carbon oxidation substances, compounds, water, ultra-low temperature liquids, gases and industrial gases. High-precision turbine flowmeters can be used for trade transfer of nitrogen oxides and gas. This kind of turbine flowmeter generally includes the function of a flow computer to correct the working pressure, temperature and fluid characteristics to achieve the precision required by the application. Sanitary Flow Meter, also called sanitary turbine flow meter or Hygienic turbine flowmeter. Ensure Accurate Flow Measurement in Sanitary food-processing and bio-technology industries.

Be careful to use turbine flowmeters when there is no lubricating fluid, because if the flowmeter is damaged too early, the flowmeter will become more and more inaccurate and ineffective. Some turbine flow meters have lubricating grease parts for non-lubricating fluids. In addition, turbine flowmeters designed for special main purposes (such as gas service projects) can generally operate within a limited temperature range (such as up to 60ºC), so actual operation at higher temperatures will destroy the flowmeter.

This type of flowmeter can be used in environmental sanitation, relatively clean and corrosive liquids with specifications up to about 24 feet. Smaller turbine flow meters can be installed in the pipeline immediately, but the size and net weight of large turbine flowmeters will have to install a lot of concrete base and support points. Pay attention to the fluidity of corrosive liquids, and pay attention to the construction materials of all wetted components, such as valve bodies, motor rotors, rolling bearings and parts.